Section 4 addresses preliminary design information and considerations for effective planning of an experiment, and establishes requirements upon which detailed final design is based. The requirements result from inherent design features of the reactor and its associated facilities, and the need to comply with established reactor safety practices and approved TREAT safety documents, administrative controls, and implementing procedures. This section is not intended to address design aspects for every potential experiment, but only the basic information to assist the experimenter in planning discussions with TREAT staff. Additional information and requirements will be supplied as needed for the specific potential experiment under consideration.

4.1 Experiment Design Requirements

The following design requirements are a direct result of the inherent design features of the Reactor and ensuring the safety of the Reactor and personnel. These requirements apply to most experiments and must be met for the experiment to be approved for insertion in the Reactor. In some instances, a written exemption may be requested by the experimenter for certain aspects where undue hazard to the Reactor or operating personnel does not exist. The written request is sent to TREAT staff with sufficient justification to support a thorough review. If approved, a written approval will be returned to the experimenter.

4.1.1 Test Vehicle Design

The test vehicle for a transient experiment will typically replace either one or two standard TREAT fuel assemblies at the center of the Reactor core. If approved during feasibility reviews, larger test vehicles may be inserted into the Reactor.

The TREAT reactor is designed to allow installation of special fuel and reflector assemblies with a viewing slot through the reactor. One set of assemblies provides a slot 3-1/2 in. wide × 22-1/4 in. high, which runs horizontally through the Reactor core or halfway through the core and reflector and continues through access holes in the shielding. Another set of assemblies provides a similar slot 2-3/4 in. wide × 48 in. high.

Neutron flux filters and shaping collars may be used to obtain the neutron flux shapes and energies required in the experiment. Since the Safety Analysis of the experiment is extremely sensitive to the type, amount, and location of the neutron flux filters, several additional requirements are called for when filters are used and certain details must be included in the Experiment Plan Package. The Experimenter should discuss this need during the Feasibility discussion and detailed information will be provided by TREAT as needed for inclusion in the Experiment Plan Package.

Use of existing electrical equipment, such as power supplies, control consoles, etc., is preferred. Any required changes will only be approved by TREAT if circuits and equipment can be returned to baseline conditions following the experiment. The experimenter should discuss any change requests during the feasibility discussion and additional detailed information will be provided by TREAT staff as needed for inclusion in the Experiment Plan Package.

The physical size of an experimental vehicle is dependent upon the size and number of TREAT fuel assemblies it replaces in the Reactor core. All TREAT fuel assemblies have a core support plate alignment fixture on the bottom and can be omitted from an experimental vehicle design.

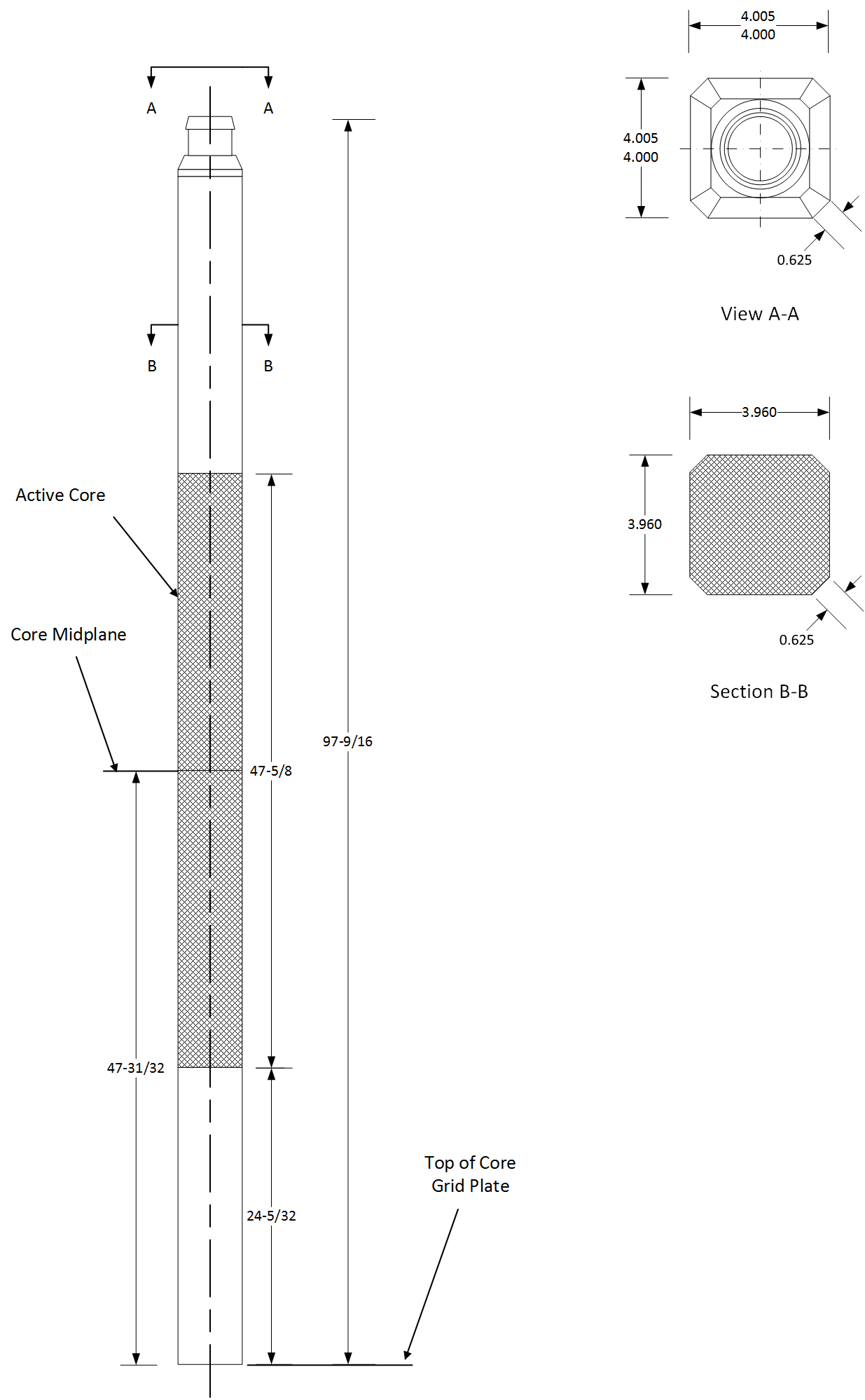

If the experiment vehicle replaces only one fuel assembly and the TREAT fuel handling casks (FHCs) are to be used, then the critical dimensions are the length of the vehicle and the size of the vehicle, measured just below the top of the fuel assemblies that are engaged with the Reactor core clamping system. The dimensions of a TREAT fuel assembly that are to be used in designing an experimental vehicle are included in Figure 7. The handling fixture at the top of the vehicle must be identical to those on the top of the TREAT fuel assemblies as shown in View A-A to allow for the cask clamping mechanism to grasp the assembly properly. Section B-B shows the cross section of the assembly below the clamping point. This top handling fixture design uses the same method of electrical connections as is used on TREAT thermocouple fuel assemblies.

If more than one TREAT fuel assembly is replaced by an experimental vehicle, the critical cross-section dimensions shown in Figure 7 must be increased by 4-in. for each assembly replaced. However, the 8-in. width and location of the radial slot in the rotating shield plug places some restrictions on the size of a vehicle that can be loaded into the Reactor.

Experiment vehicle number, size, the use of the FHCs, and the need for a mechanical hold-down shall be assessed during the feasibility discussions and safety analysis. Additional detailed information will be provided by TREAT staff as needed for inclusion in the Experiment Plan Package.

Figure 7. TREAT fuel assembly dimension (in.)

4.1.2 Containment Requirements

Single containment of test specimens (i.e., in addition to test specimen cladding) is acceptable if the fissile material inventory, determined by fission during the transient test is limited to 235U. Also, all materials in the test vehicle must essentially be noncorrosive to zircaloy, stainless steel, aluminum, or graphite. The containment must also be designed to retain its integrity during all planned test and credible accident conditions, including the maximum unplanned reactivity addition as described in Section 5.3.12. Exceptions to this requirement apply to a new form of a TREAT driver fuel element being tested in TREAT (i.e., low-enriched uranium conversion lead test assembly) and fresh (unirradiated) calibration fuel for a calibration run. If either exception exists, it should be included during the feasibility discussion with TREAT staff.

Double containment is required for all test specimens containing plutonium, 233U, or an inventory of fission products from previous irradiation that is greater than what will be produced during the transient test. It is also required if materials significantly corrosive to zircaloy, aluminum, stainless steel, or graphite could be released from the test specimen or the primary containment. The primary containment shall be designed to retain its integrity during all planned testing conditions. One level of containment must be ensured during credible accident conditions, including the maximum unplanned reactivity addition as described in Section 5.3.12.These requirements for double containment are independent of any shipping requirements.

If mechanical seals are used on the primary or, for double containment, on both the primary and secondary, a finite leak rate may be expected. The test vehicle design requirements shall specify the maximum acceptable leakage from each mechanical seal and the total from all such seals at time of vehicle assembly. An important factor to be addressed in the containment and leakage criteria is the release of fission gases during extended post-experiment storage at TREAT. Each experiment shall be analyzed as appropriate for its design, fission product content, operating and test conditions, accident conditions, etc. TREAT staff will provide additional detailed information to assist the experimenter with calculating this information and including it in the Experiment Plan Package.

4.1.3 Shielded Cask Designs

Shielded casks are normally required for the safe handling of experiments due to the very high radiation levels that build up in the test vehicles during a transient run. Two casks are available for handling experiments at TREAT, the fuel-handling cask (FHC) and the TREAT loop-handling cask (TLHC). The FHC is designed specifically for loading and unloading fuel assemblies at the Reactor. It will handle only one fuel assembly at a time, which has the same general design as a TREAT fuel assembly, including the top handling fixture. The TLHC is used for handling experiments that are too large to fit in the FHC. A separate shielded cask is available for transportation of radioactive experiments between TREAT and nearby hot cell facilities.

The TREAT Facility does not supply shipping casks for transportation of experiments to or from TREAT. This is the responsibility of the experimenter. The use of all casks must be coordinated with TREAT to ensure that casks can be handled and used safely and properly at the TREAT Facility.

For disposal and transportation purposes, all hazardous material, e.g., Na, Cd, Be, as listed in 40 CFR 260 and 261, and their quantities must be listed in the design description of the test vehicle. The latest revisions of the transportation regulations must be complied with.

4.1.4 Experiment Identification

TREAT will ensure that each individual experiment is given a unique and legible identification code that does not conflict with previously used codes. Identification codes are alphanumeric and sufficiently unique to avoid any misidentification of the data packages or experiment hardware. TREAT will provide the experimenter additional guidance on acceptable placement of experiment identification prior to shipment.

4.1.5 Coolant Environment

The Reactor is cooled by air, and any test vehicle placed in the reactor will be in contact with this cooling air. Heat transfer from an experiment to adjacent TREAT fuel, when combined with nuclear heating of this TREAT fuel, shall not cause the cladding of this TREAT fuel to exceed 600°C under normal conditions or 820°C under maximum accident conditions. The safety analysis will include the full analysis performed on heat transfer.

4.1.6 Criticality Conditions

The sealed experiment apparatus must be subcritical when submerged in water. Also, the maximum quantity of fissile material allowed in one experiment apparatus assembly is 8 kg U-235 (or equivalent amount of Pu-239 + 241 and/or U-233). A maximum of 1 kg of hydrogenous moderator material may be associated with the fissile material in the experiment apparatus. The equivalent amount of Pu-239 + 241 and/or U-233 is expressed in terms of U-235 by use of an equivalency factor of 1:4. For example, 1 kg Pu-239 + 241 (and/or U-233) will be considered as 4 kg of U-235. If the test element is to be stored at TREAT, the maximum amount of the above fissile material that can be stored is one half the amount allowed in the experiment apparatus.

When unirradiated fissile material (cold pins, flux monitor wires, foils, etc.) is required for an experiment, only the minimum amount of fissile material required for the experiment shall be sent to TREAT. There is a further limit on the amount of fissile material in the form of cold fuel pins that can be stored at TREAT. The experimenter will discuss materials to be shipped prior to shipping, especially any cold fuel pins containing plutonium, to ensure TREAT has adequate storage available. The experimenter is responsible for return shipping of any spare fissile material from TREAT immediately following completion of an experiment.

4.1.7 Flux Monitor Wires

When flux monitor wires are required for an experiment, they shall be individually enclosed in metal or metal foil and identified by the experimenter discussed with TREAT staff prior to shipment. Placement of flux wires on the test element must be protected from the possibility of accidental dislodging and becoming lost in shipment and placement in storage.

4.1.8 Codes and Standards

The experiment shall comply with all applicable codes and standards that are in effect at the time of the design and operation of the experiment. TREAT staff will provide the experimenter with the most current information.

4.2 Experiment Handling Hardware

Permanently affixed or separately provided experiment lifting hardware required for experiment handling shall be supplied by the rxperimenter unless standard hardware is available at TREAT, such as cranes, slings, eyebolts, and shielded casks. There are specific requirements for the rated safe working load of lifting hardware, marking hardware with safe working load, and periodic load testing of the hardware. TREAT will provide additional guidance to the experimenter as required.

4.3 Experiment Equipment

The experimenter is encouraged to use TREAT experiment support equipment when available and appropriate to meet the need, such as instruments and shielded containers for transporting radioactive material. Electrical, water, and compressed-air connections are also provided by TREAT. Considerable time may be required to procure and install additional equipment if the experiment requirements cannot be met through TREAT supplied equipment. The experimenter should discuss this potential need with TREAT staff to ensure schedule delays are minimized.

4.4 Experiment Data Collection

Three separate systems exist at TREAT for recording data during transients. One system is built into the automatic reactor control system (ARCS) computers. The second system is referred to as the data acquisition system (DAS) and is made up of modern hardware and Labview-based software. A private Ethernet connection is available to experimenters that includes Reactor data as near real-time Labview shared variables. The ARCS control and monitor node computers collect and record all reactor parameters independently of the DAS and are the primary recording systems for reactor parameter data. The third system records data from the hodoscope detectors. TREAT staff will supply additional information if needed.

Forms for recording experimental data shall be provided by the experimenter with one copy of each filled-in form provided to TREAT staff for facility files. For data obtained in the form of an oscillograph record from the experimenter's equipment, the experimenter must submit a copy of the record, a copy of the digitized data obtained from the record, or curves obtained from the record.

The original records from the facility's ARCS data acquisition system are retained at the facility, but a copy of the digitized data from these records will be supplied to the experimenter on request. TREAT will supply additional information related to the systems and requirements based on the parameters of each experiment.

4.5 Computer Systems

If an experimenter-supplied computer or a computer system is required for a specific experiment or series of experiments it must be in compliance with DOE Order 1360.2B, "Unclassified Computer Security Program." Upon notification from the experimenter that this is required, TREAT staff will provide additional guidance and forms to support compliance.

4.6 Support Facilities

Some experiment services may be performed at other INL support facilities. TREAT will discuss these needs with the experimenter as they arise and provide additional information as needed for planning and scheduling.

4.7 Planning Experiment Schedules

The experimenter must set and communicate to TREAT staff target schedules as part of initial experiment planning. This provides a basis for TREAT staff to develop plans and schedules in collaboration with appropriate INL support facilities. All potential schedule conflicts will be discussed for resolution prior to final scheduling in the Experiment Plan Section 5.1.11.