Mission Statement

Provide a family of irradiation vehicle capabilities that provide environments representing water-cooled power reactors up to the conditions found in pressurized water reactors (PWR), each with a different focus area. These include increased specimen throughput, simulation of loss-of-coolant accidents (LOCA), or full flow forced convection.

System Description

Development of TREAT's water-reactor family of irradiation rigs is well underway. Their capabilities are summarized below:

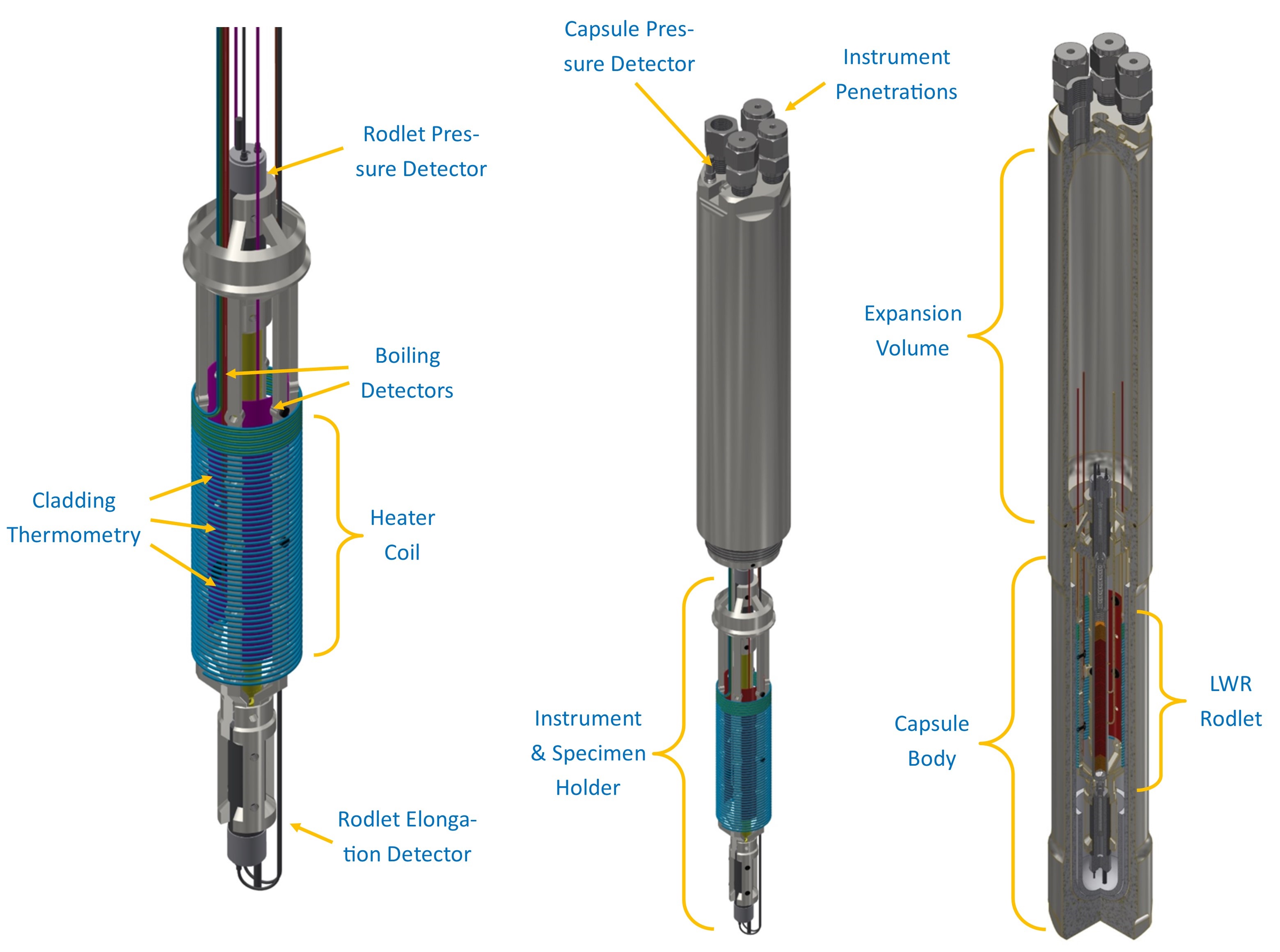

MARCH-SERTTA (pictured above): The Static Environment Rodlet Transient Test Apparatus (SERTTA) module for the MARCH irradiation vehicle system (MARCH-SERTTA) consists of a small water-filled capsule housed within a larger containment pipe. It enables affordable and high-throughput water-based testing. The capsule can house one rodlet (≤10 cm fuel length) or similar specimen in a water environment. The water can be heated before the transient to give elevated temperature and pressure water or steam environments. MARCH-SERTTA is outfitted with detectors to indicate environment pressure, environment temperature, fuel cladding temperature, fuel internal pressure, fuel axial expansion, and water phase change. These provide a full suite of fast-response data for evaluating specimen boundary conditions, determining the timing of crucial performance transitions, and comparison to transient fuel performance models.

Super-SERTTA: Super-SERTTA enables irradiation of larger rodlets in one large capsule. This approach enables enhanced instrumentation while greatly facilitating through-the-top specimen loading for hot cell use. Electric heaters and pipe cooling lines can establish natural convection water circulation prior to the transient. Ideally suited for high-value pre-irradiated specimens, Super-SERTTA test trains can be adapted to suit reactivity-initiated accident testing as needed, but its greatest strength lies in its ability to simulate LOCA events via depressurization valves and expansion tanks.

TWERL: The TREAT Water Environment Recirculating Loop (TWERL) combines all the features of the Super-SERTTA with a compact high-pressure water pump to enable forced convection cooling for up to four rods at full PWR cooling rates, or up to nine rods at reduced cooling rates. TWERL is designed for tests that require forced convection to achieve prototypic phenomena timing in water phase change events while supporting tests of bundle-scale interactions. TWERL represents the pinnacle of water-cooled reactor engineering scale tests in TREAT for licensing and other highly prototypic tests. TREAT's uniquely capable core can drive a high-burnup center rod in a nine-rod bundle up to and beyond current regulatory limits for state-of-the-art fuels.

Applications

TREAT's suite of water-based irradiation capabilities is ideal for development and testing of water-reactor fuels, including current fleet designs and advanced designs with enhanced accident tolerance.

Specifications

Pre-transient water temperature: Up to 280°C

Pre-transient water pressure: Up to 15.5 MPa

Maximum fuel enthalpy: Design optimized for LWR regulatory threshold energies (e.g., 711 J/gUO2), but up to 2,000 J/gUO2 can be achieved if desired*

*Based on maximum capsule capacity on a rodlet containing eight PWR-diameter 4.95% enriched UO2 pellets