Mission statement

Provide the means to measure critical safety performance parameters for a variety of experiments by developing and qualifying sensors and other in-pile instrument technologies.

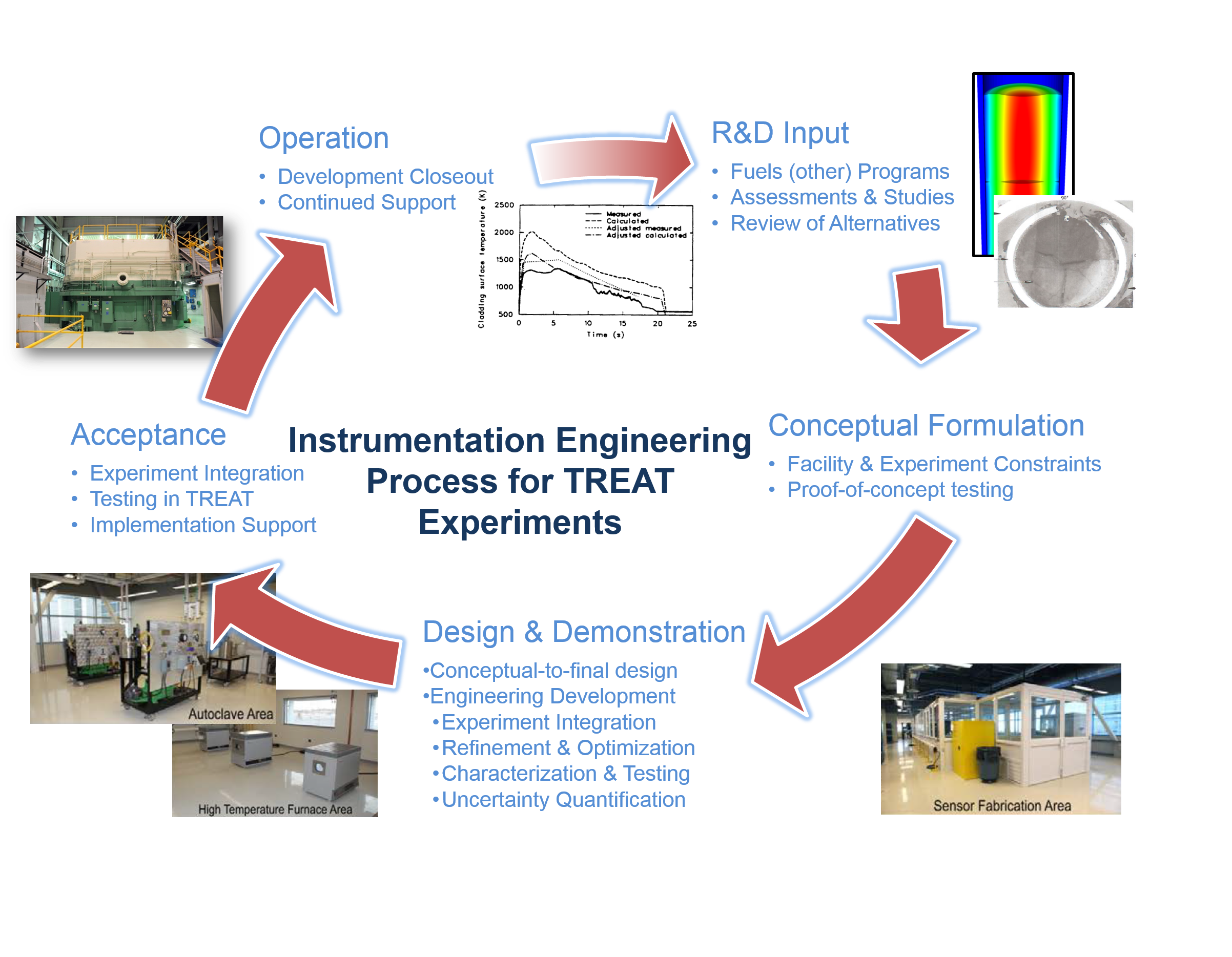

System description

Advanced instrumentation is key to unraveling the complex multiphysics involved during transient irradiation experiments. This includes development and validation of modern modeling and simulation tools. A science-based, engineering focus for nuclear fuels and materials development requires access to data streams beyond those that have historically been available. Successful development of advanced fuels and materials hinges on well-coordinated and innovative instrument R&D.

The TREAT facility provides a flexible environment for development and qualification of instruments used in in-pile transient testing. Using a science-based approach capitalizing on modern modeling tools, theory, and experimentation, researchers are performing R&D to establish a selection of instrumentation technologies with defined measurement output uncertainties. In particular, the instrumentation R&D group at the High Temperature Test Laboratory at INL provides expertise and key facilities (e.g. furnaces, coolant environments, etc.) that support measurements in experiments at the TREAT facility.

Key measurement capabilities:

- Neutron (and gamma) flux: Up to 1017 n·cm-2·s-1 with < 1 ms response

- Temperature: Up to 3,000°C including high speed and non-contact approaches

- Pressure: High speed (<1 ms response) up to 10,000 psi

- Specimen elongation/deformation: < 1 ms response

Available sensor technologies include:

- Dosimetry – wires, foils, etc.

- Self-powered neutron (and gamma) detectors

- Miniature fission chambers

- Thermocouples (various types and configurations for specific applications)

- Optical fiber based sensing

- Infrared pyrometry (for non-contact and high temperature applications)

- Interferometric sensors for temperature, pressure, and composition

- Ultrasonic technologies including ultrasonic thermometers (capable of high temperature measurement)

- Linear Variable Differential Transformers (LVDT) technology for pressure and specimen deformation, flow rate, etc.

- Electrical impedance-based sensing used for boiling detectors and deformation sensors

- Commercially available transducers including strain gauge, capacitance, piezoelectric-based technologies for pressure, strain, acoustics, etc. — in-reactor use may require special adaptations and/or characterization

- Flow meters

- Innovative measurement systems for material properties and fundamental studies

- High-speed video

Applications

Examples of applications relevant to advanced in-pile instrument development and qualification:

- Real-time, spatially resolved radiation fluxes

- Fuel and cladding temperature

- Fuel rod plenum pressure for fission gas release

- Fuel and cladding elongation

- Cladding failure detection

- Cladding-to-coolant heat transfer

- Coolant pressure, temperature, and flow rate

- Fission product transport

- Material properties

Relevant characteristics of the TREAT facility

- Dry core design provides variety of options for access

- Experiment environments may be quite harsh (postulated reactor accident conditions) and varied (gas, liquid; H2O, Na …)

- Experiments typically arrive in packaged-devices with instrumentation, inserted into center core location — integration of instrumentation into experiment devices is generally non-trivial

- Peak neutron flux ~1017 n·cm-2·s-1

- Max neutron fluence ~1016 n·cm-2

- Gamma heating may be very high (~150 ΔK for stainless steel peak)

- Response time and data acquisition rates are crucial

- Relatively short wire runs (~10-20 m)

- Ideal "playground" for in-pile instrumentation R&D